Injected Products

In 2010 we invested in inyection machines to diversify our market.

Having this equiment, made us able to help our costumers in give them the optimal product in the best cost possible being more competitive.

Some applications are:

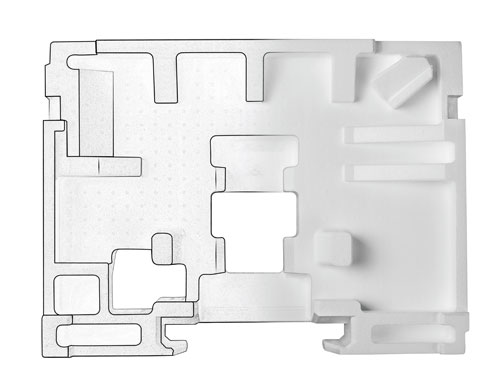

For packing

Having the EPS packing injected, means you are offered the best cost possible for the final client, and excellent image that protects and care the product.

We usually analize the tooling investment vialibity, budget, designe proposals and possible combinations of it. All the important matters for our costumer.

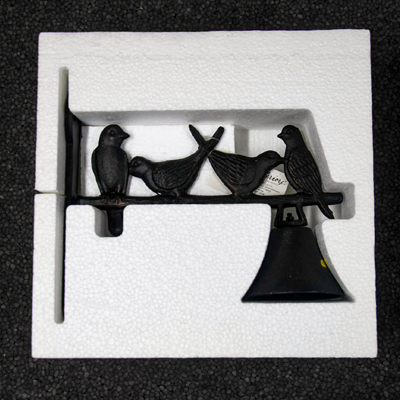

For school and craft

The need is not only industrial. The decoration sector, craft and academic are very important to us; The basic products that we managed are the eps sphere, eps eggs, tortilleros, skulls, mannequins, hats, etc.

The Cooler

The Cooler has an infinity uses, according his size, capacity, and density. The first function being to isolate and protect. The EPS cooler has an infinity markets: retail consume, fishing, pharmaceutical, food indusrty, health-care industry, etc.

The Seedbed

According to the plant to sow; and the space and production need it, it will be the seedbed size. This is a very nice and noble product in the agriculture market if its selection is adecuated. His durability depends in how is managed, but at least it can be considered for two seasons.

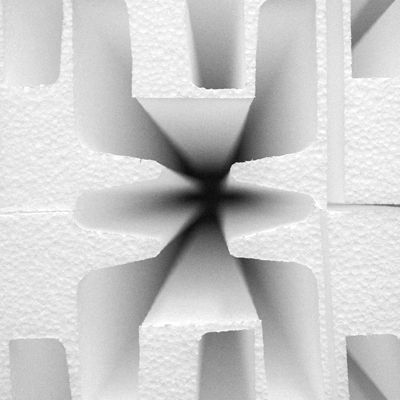

Cut-wire Products

Aisla Pak started from day one with cut-wire EPS Products. We are used to work with different variety of densities (from 10k/m3 to 60k/m3). Our process controls help us to the continuous improvement. Pushing our system to innovate and always looked for a better proposal for our customers.

There are some important markets to mention:

To packing

It is part of our culture to let know our costumers if it is better to have an EPS Cut-wire packing. It could be a matter of volume, easy to cut or investment in a tooling. Wherever the reason is, a cut-wire eps packing is an excellent choice to consider. Low price, easy, quality, good presentation. We usually run some pilot density tests, certificated the quality and in matter of days start productions in series. It is very common to see a wide products in industry protected by some EPS squares.

Industrial consumption

There is an infinity of industries that use the EPS for internal consumption. This is mainly because of the material nature: flexible, protect, isolate, economic, no fungus generation, cushion for impacts, among others. We have seen it in markets such as refrigeration, ceramics, furniture, all kind of doors, glass, automotive and many more.

For school and craft

The EPS cut-wire material is very versatile in this sector. We have accomplish to delivery an infinity of products: like spheres, letter, numbers, phrases, figures, frames, etc. There are products available for all kind of events; like birthdays, weddings, baptism, or any other special theme. Also, there is cut-wire products for every season, such and Christmas, Spring, Easter, etc.

The EPS Plate has an important place in the business. The costumer is beyond creative and with this product any design is possible. Being such an easy material to “modify” the costumer can create almost everything he can imagine.

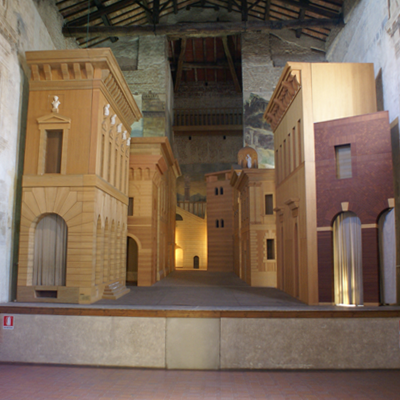

For scenography

Like how we had mention it before, the nature of product has allowed us to cut almost anything. We had seen castles artworks, dinosaurs in real size, where in which we had provided with the products, but the artist o producer can accomplish almost anything; with the EPS.

For geofoam

Blocks have various measures but the standard is 2.44mx 1.22mx 1.00m basically, to fill in constructions of the stadiums, highways, bridges, landscaping, etc. The properties have to reach their density until 48kgs/m3 without deforming for its durability. In construction achieving to obtain a material that is very attractive in cost and also in time.

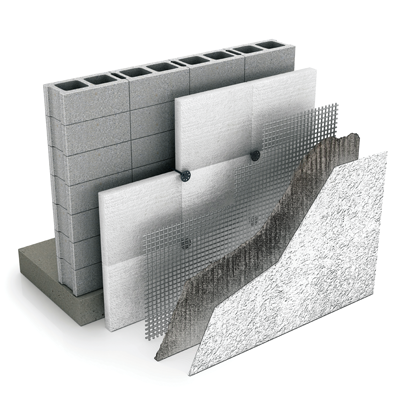

For insulation

The use from EPS like a thermal insulation, allows to an important save in energy (either for air conditioning trucks, refrigerators, etc.) Other advantages of use, for example:

- Material extraordinary light weight and resistant.

- Cushion on impact.

- Properly behavior against water and resistant to the steam diffusion.

- It provides chemical and mechanical resistance.

- Totally hygiene: doesn’t get moldy or rot.

- Easy to manipulate and to install.

For construction

The industry of construction in Mexico, it already has established his constructive process: Strongly positioned the products of EPS that we manage:

- The Vault (together with the present joist are advantages in isolation and time resource in construction, refills saved like on concrete).).

- The caseton like a filling material at a lowest cost, density and save in concrete is an excellent option.

- The lightening pearl of roofing, mix with the concrete accomplishes the insolation and low cost.

- GEOFOAM We mention it again, how constructive is for big construction sites, it’s a filling on high density, it can save material, time and stability on construction sites

- The plate with that density and thickness appropriate an excellent insolation, in cold countries that uses thickness highly in every wall, that helps a lot to extreme temperature.

Español

Español